╱Our History

We produces best-in-class gray iron, ductile iron, austempered ductile iron, manifold, wind turbine brake and Hi Si-Mo ductile iron castings at headquarter in Taiwan. WKM is committed to relentless improvement, forward-thinking sustainability initiatives, and providing a reliable experience to the global customers.

We are a medium-sized, customer oriented sand casting and precision machining company in the east Asia area of Taiwan.

We supply a wide range of customers with our high-quality castings like Automotive (manifold, brake, housing ), Construction(york, rotor), Green Power(wind turbine brake), and Agriculture (housing, bracket), etc.. Our multifaceted production processes enable us to design and produce your components economically.

We work hard to support our companies with the goal of maintaining a “customer first” culture built on continuous improvement, problem solving, and innovation. As a group, from the main office to the shop floor, we are dedicated to providing value-add manufacturing services and solutions for our customers.

- 1969

World Known Mfg. Co., Ltd founded at Taichung, Taiwan

- 1984

World Known Mfg. Co., Ltd founded at Taichung, Taiwan Established automatic molding line and produced ductile iron auto parts

- 1986

Machining shop established for brake disc rotors and drums.

- 1988

Signed sales and technical assistance agreement with Automobile Foundry Co.,Ltd.(JIK Japan) and started exporting auto parts to Japan

- 1991

Became Joint Venture to Mitsubishi Corp. and Automobile Foundry Co.,Ltd (Branch of Isuzu)

- 1992

Set up the second automatic molding line

- 1995

Approved as an ISO-9002 certified organization

- 1998

Approved as a QS-9000 certified organization

- 2001

Supply Machined Engine Parts to Cummins Engine Co.

- 2002

Approved as an ISO/TS-16949 organization

- 2004

Establishment of World Know Precision Industry Co. Ltd., (Fuzhou, China)

- 2005

Introduced ERP(Enterprise Resource Planning) IT software to improve Daily management.

- 2008

Serial production of brake components for Wind Power industry

- 2011

Started producing and assembling casting parts for Fuel cell industry

- 2013

Renew automatic molding lines with DISA machines in May

- 2014

Start supplying parts to Cummins Komatsu Oyama (KCEC)

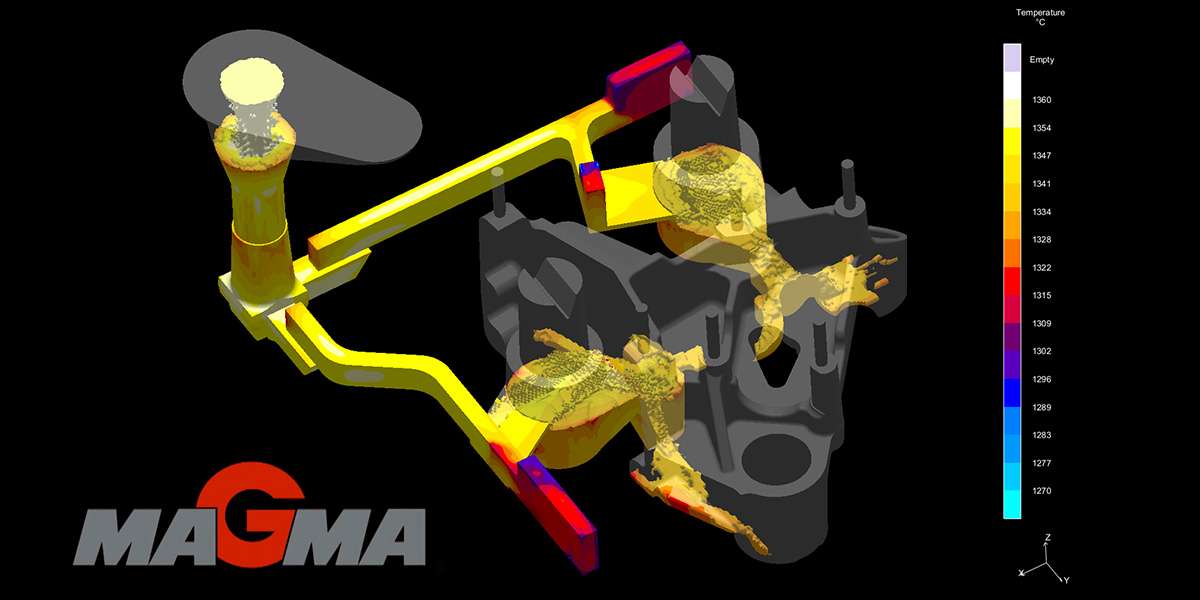

- 2015

Introduce MAGMA solidification simulation software